Optimized Mould Design with Advanced Moldflow Simulations

Precision Engineering for Superior Performance

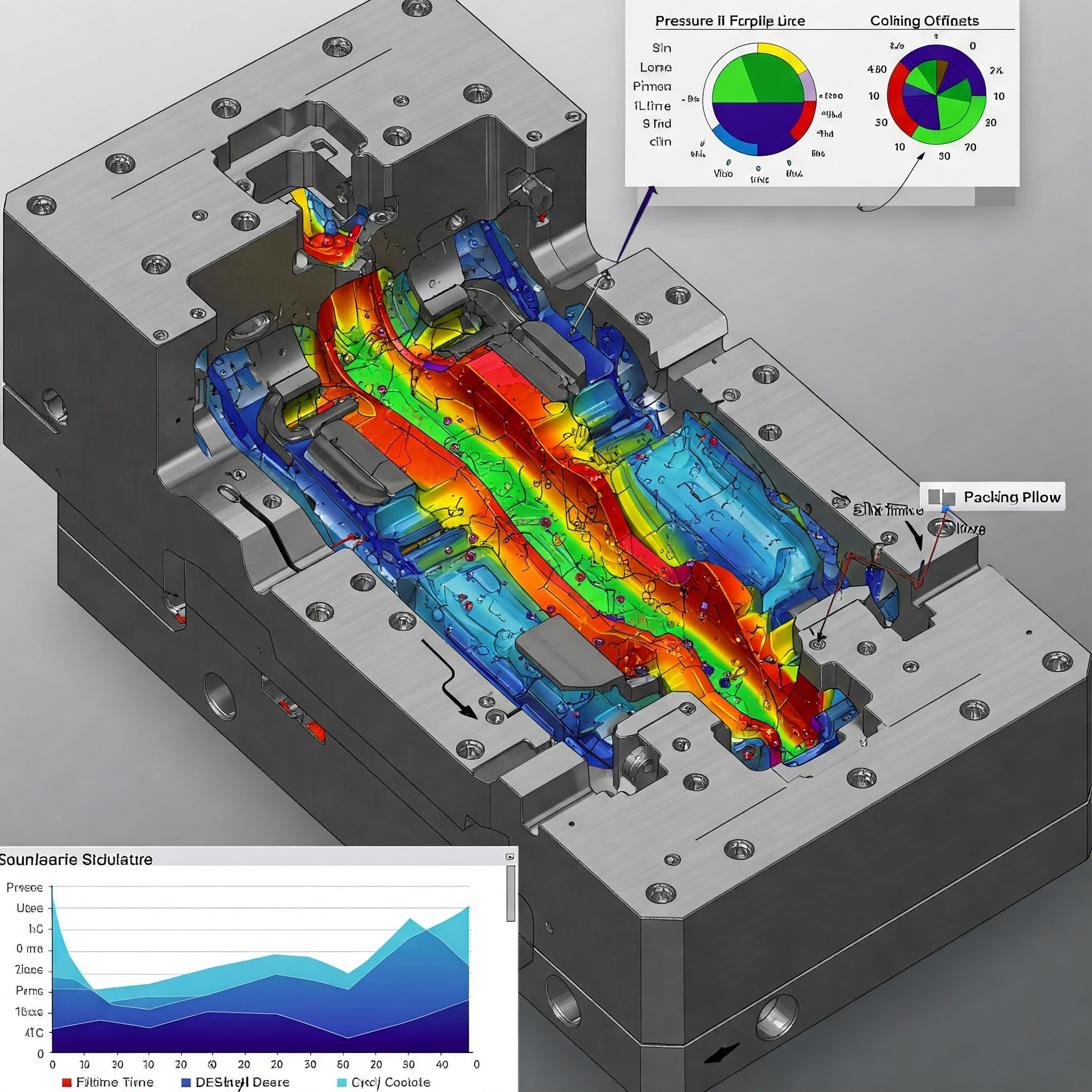

For over a decade, Sahil has been utilizing Moldflow simulation software to enhance the efficiency and precision of injection moulding processes. By leveraging the powerful Moldflow-Insight module, we gain detailed insights into injection dynamics, pressure distribution, and cooling optimization before production even begins.

Our advanced in-mould simulations allow us to identify degassing points early in the design phase, ensuring a streamlined production process. Additionally, simulations of shrinkage and warpage simplify mould dimensioning, while core displacements and stress analysis help prevent structural weaknesses during injection moulding.