Comprehensive Product Design & Development

From Concept to High-Performance Moulds

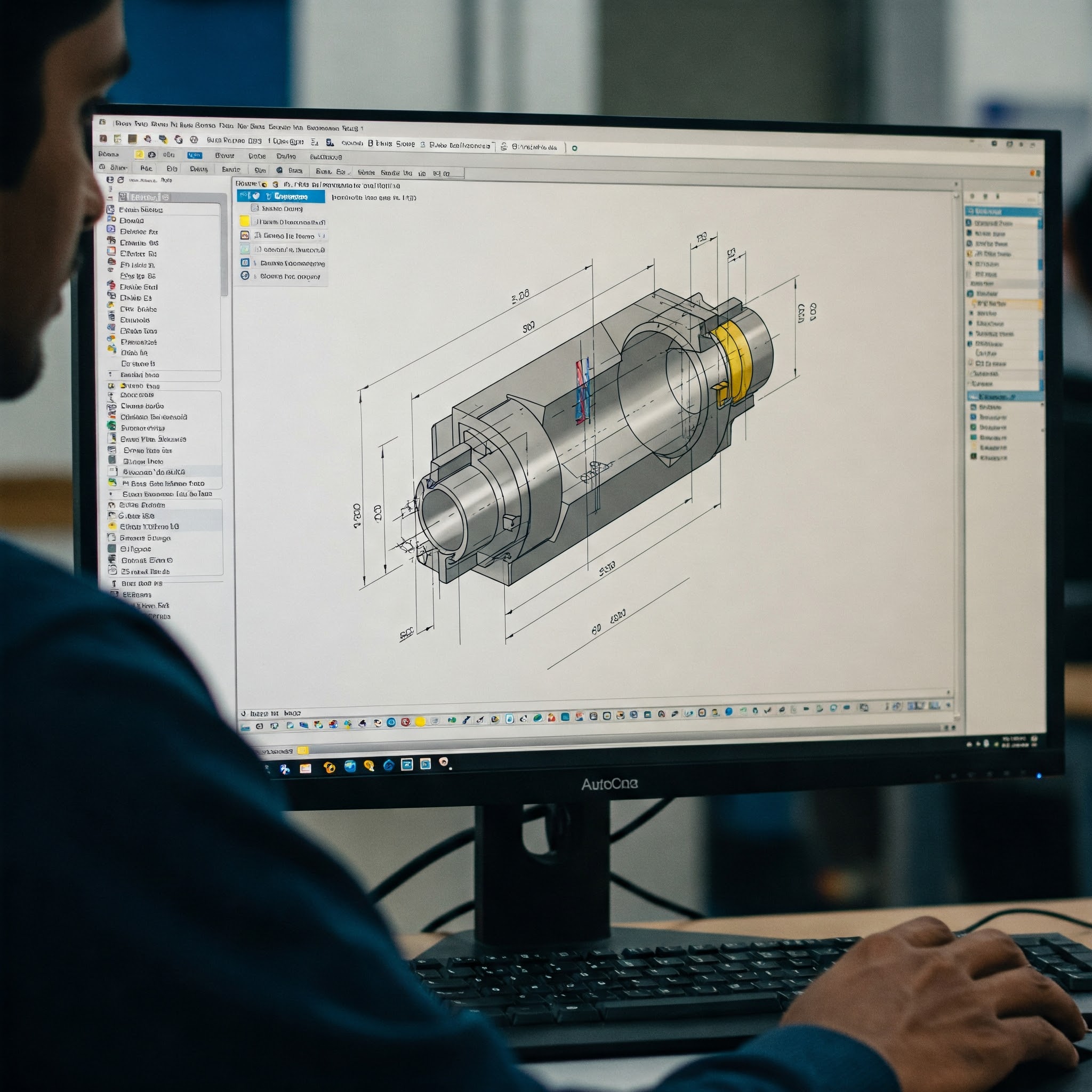

Beyond manufacturing precision injection moulds, Sahil offers end-to-end product design and development for injection-moulded components. Our process begins with a thorough consultation to understand specific component requirements and deliver tailored solutions.

Sahil oversees the entire component development journey up to the first series of production, ensuring designs optimized for plastic moulding. By eliminating unnecessary material accumulation, we prevent prolonged cycle times. Using advanced Moldflow simulations, we verify optimal component filling.